| Universal Controlled Pore Glass (CPG) as a Solid Support Material

In the fields of organic synthesis, combinatorial chemistry, and particularly oligonucleotide (DNA/RNA) synthesis, the use of a solid support is a fundamental principle of the solid-phase synthesis technique pioneered by Bruce Merrifield. Among the various support materials available, Controlled Pore Glass (CPG) stands out as a gold standard, especially for automated synthesis. Universal CPG refers to a specific type of CPG that features a terminal hydroxyl group protected by a photolabile or acid-labile protecting group, allowing it to be functionalized with the first monomer after its synthesis. This “universal” nature provides unparalleled flexibility compared to pre-loaded supports.

1. What is Controlled Pore Glass (CPG)?

CPG is a high-silica glass that has been subjected to a controlled manufacturing process (phase separation and acid leaching) to create a rigid, porous matrix with a very narrow and defined pore size distribution.

• Composition: Primarily silicon dioxide (SiO₂).

• Structure: A rigid, sintered network of silica particles creating interconnected pores.

• Key Parameter – Pore Size: This is the most critical specification. Pore size, measured in Angstroms (Å) or nanometers (nm), determines the size of the molecules that can be synthesized on the support. Common pore sizes include:

(1). 500 Å: Standard for short oligonucleotides (up to ~50 bases).

(2). 1000 Å: Preferred for longer oligonucleotides (50-100 bases) as it provides more space for chain elongation, reducing steric hindrance.

(3). 2000 Å & higher: Used for very long sequences (>100 bases), peptides, or other large molecules.

2. The “Universal” Concept: How it Works

A “Universal” support is distinct from a “pre-loaded” or “sequence-specific” support.

• Standard (Pre-loaded) CPG: The first nucleotide (e.g., dA, dC, dG, dT) is covalently attached to the CPG during its manufacture. To synthesize a sequence ending in “A”, you must purchase dA-CPG. This requires maintaining an inventory of all four nucleoside-CPG types.

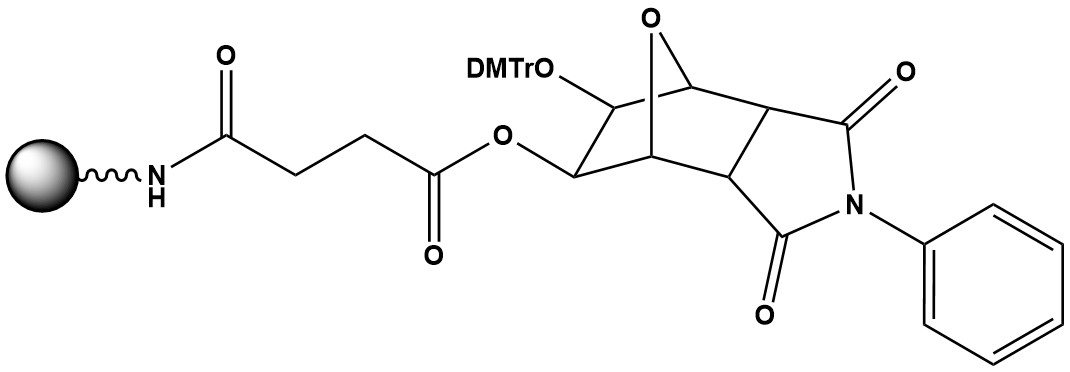

• Universal CPG: The CPG is functionalized with a spacer arm (e.g., long-chain alkylamine, LCA) that terminates in a reactive group (often a hydroxyl) protected by a universal protecting group.

(1). Common Protecting Groups:

• Photolabile (e.g., NVOC, MeNPoc): Removed by UV light (~365 nm).

• Acid-Labile (e.g., DMT, MMTr): Removed under mild acidic conditions (similar to the detritylation step in oligonucleotide synthesis).

(2). The Process:

• Deprotection: The universal protecting group is removed from the bulk Universal CPG.

• Coupling: The first monomer of any desired sequence (which has its 5′-end protected and 3′-end activated) is coupled to the now-exposed hydroxyl group on the CPG.

• Standard Synthesis: The synthesis then proceeds as usual, building the oligonucleotide from the 3′-end towards the 5′-end. The key advantage is that the same batch of Universal CPG can be used to start the synthesis of any oligonucleotide sequence, regardless of the 3′-terminal nucleotide.

3. Key Properties and Advantages of Universal CPG

• Excellent Chemical Stability: CPG is inert to the harsh reagents used in synthesis (acids, bases, oxidizers, organic solvents).

• Rigidity and Mechanical Strength: Unlike polymer supports like polystyrene, CPG is non-compressible. This allows for high flow rates of reagents and solvents through the synthesis column without clogging or channeling, which is crucial for efficient coupling and washing in automated synthesizers.

• High Loading Capacity: The high surface area of the porous structure (typically 50-150 m²/g) allows for a high density of functional groups (loading capacity), often in the range of 20-100 µmol/g. This enables the production of substantial quantities of product.

• Well-Defined Pore Size: The controlled porosity ensures predictable diffusion of reagents and solvents, leading to consistent and high coupling efficiencies (>99% per step), which is essential for synthesizing long sequences.

• Universality and Flexibility: As described, a single inventory of Universal CPG supports all synthesis needs, simplifying logistics and reducing costs.

• Excellent Swelling Properties: CPG is a rigid material that does not swell or shrink in different solvents, ensuring consistent column packing and reagent flow throughout the synthesis process.

4. Limitations and Disadvantages

• Fragility: While rigid, glass is brittle and can be ground into fines (fine particles) if handled roughly. These fines can clog frits in synthesis columns.

• Limited Pore Volume for Very Large Molecules: Although high pore sizes are available, the synthesis of very large biomolecules (e.g., long peptides or proteins) is still better suited to highly swollen polymer supports.

• Silanol Groups: The surface contains residual silanol (Si-OH) groups that can be reactive and lead to non-specific adsorption or side reactions if not properly capped during manufacturing.

• Cost: Generally more expensive to produce than some polymeric supports like polystyrene beads.

• Density: CPG is denser than solvents, meaning it settles quickly. This is generally not a problem in packed columns but can be a consideration in certain batch synthesis modes.

5. Primary Applications

• Oligonucleotide Synthesis: The dominant application. Used in synthesizers for research, diagnostics, and therapeutics (e.g., primers, probes, aptamers, antisense oligonucleotides).

• Peptide Synthesis: Less common than for oligonucleotides, but used, especially for difficult sequences where its rigidity is beneficial.

• Combinatorial Chemistry: For creating libraries of small molecules.

• Solid-Phase Organic Synthesis (SPOS): A general support for a wide range of organic transformations.

• Chromatography Media: The base material for size-exclusion chromatography columns. Universal Controlled Pore Glass remains a premier solid support material, particularly in the field of automated oligonucleotide synthesis. Its combination of mechanical rigidity, chemical inertness, high loading capacity, and well-defined porosity makes it uniquely suited for applications where high efficiency and reproducibility are paramount. The “universal” functionality elevates its utility by providing unmatched flexibility, streamlining the synthesis process, and reducing inventory complexity. While alternative supports like functionalized polymers have their place, especially in peptide synthesis or batch-mode reactions, Universal CPG’s performance in flow-through systems solidifies its status as an indispensable tool in modern chemical and biological laboratories.

References

1. Oligonucleotide

2. Oligonucleotide synthesis

3. Solid-phase oligonucleotide synthesis

4. Synthetic DNA Synthesis and Assembly: Putting the Synthetic in Synthetic Biology |